EMTS (Electric Monorail Transport System)

The EMTS (Electric Monorail Transport System) has particularly been designed for the underground transport of men and material in non-explosive atmospheres. With a load carrying capacity of 30 tons and the ability to drive systems gradients of more than 30 degrees the EMTS can make transport in inclined gateroads considerably more efficient.

Features

- Self-propelled monorail with integrated electrical hoisting devices

- High torque electrical devices

- Frequency converter technology including energy recovery

- 4 drive units with total pulling force 80 kN

- Load monitoring and control system

- Driver cabin with on board diagnostic and multifunction joystick

- Trap-guided trolleys with fail-safe brake system

Advantages

- Flexible transport of equipment, material and men

- Zero-emission transport technology continuous to go from 0-30 degrees incline

- Smooth and efficient speed control for safe and comfortable operation

- High speed (up to 3.5 m/s) and powerful transport of heavy loads (up to 30 tons)

- Short instruction time, simple operation and high availability

- Safe operation, certified according to international standards

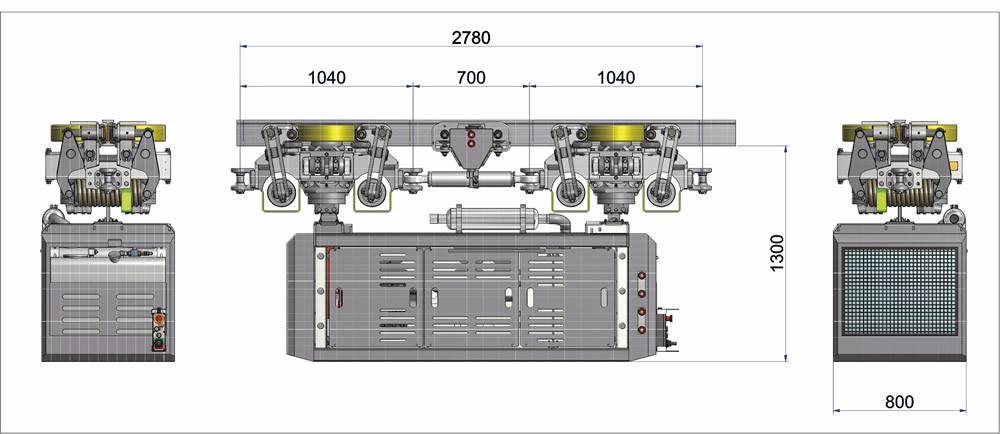

- Technical data EMTS 2+2